VMP

VMP

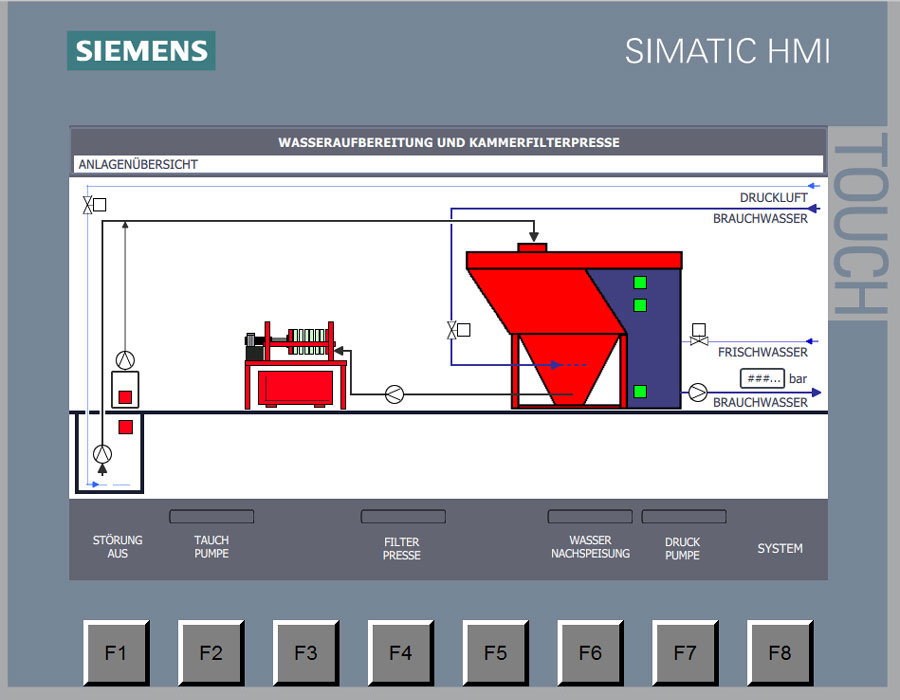

Automated water treatment plant with obliquely-arranged lamellar clarifier, chamber filter press and Siemens PLC with touchscreen display.

-

Obliquely-arranged lamellar clarifier

The process water suspension accumulating in production is guided to a dirty water collection basin. This is pumped by a specially designed submersible pump to the obliquely-arranged lamellar clarifier to be clarified.

The process water flows from the production through the specially coated honeycomb structure. With this honeycomb structure, the obliquely-arranged lamellar clarifier performance is 10 times greater than a conventional sedimentation tower.

The solid particles in the dirty water are separated by the physical flow process of the solid/liquid separation and sedimentation in the particle hopper. The sediment concentrated here can be dehydrated further via a chamber filter press. The water cleaned in the lamellar clarifier flows over an overflow to a separately provided fresh water tank and is then returned to the process water circuit.

The obliquely-arranged lamellar clarifier is equipped with a manual flushing function.

ECS obliquely-arranged lamellar clarifier operate without the addition of additives.

Technology

- Obliquely-arranged lamellar clarifier with specially coated lamellar packages and ECS honeycomb structure

- Clarifying performance 10 times greater than conventional sedimentation towers

- Stainless steel inlet screen

- Manual flushing function of the lamellar clarifier via valve

Option

- Integrated fresh water tank

- Special offshore sea water coating of the clarifier

- Metering station for addition of additives

-

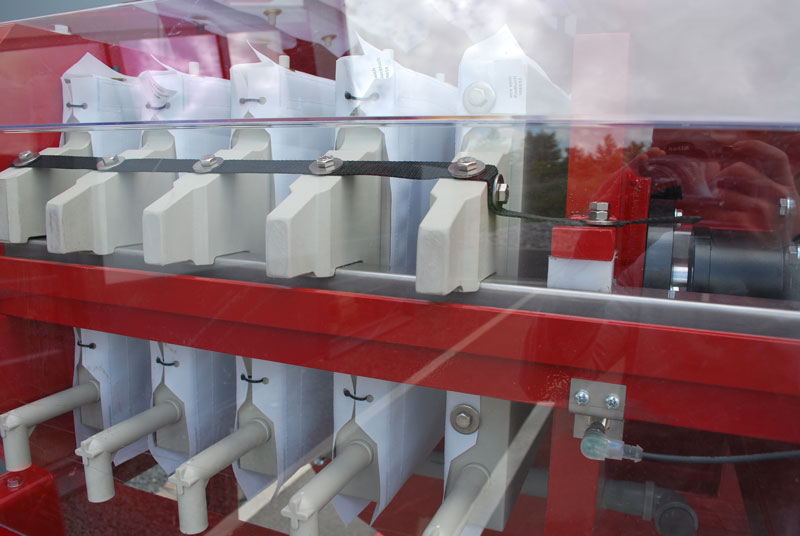

Chamber filter press

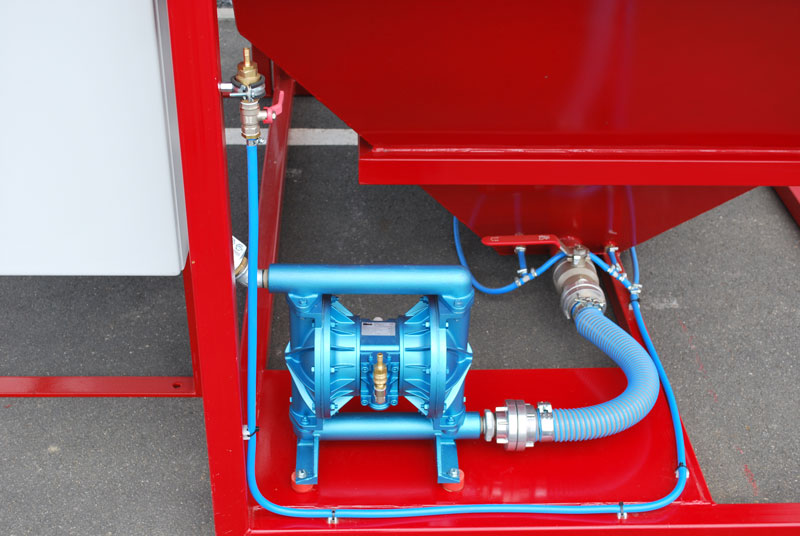

The sediment concentrated in the lamellar clarifier is pumped to the chamber filter press by means for further drainage by means of a diaphragm pump. The filtrate water drains through a droplet channel and is returned to the production circuit. The degree of drying of the filter cakes can be individually adjusted and is monitored by a water sensor.

If the setting for the degree of drying of the filter cakes is reached, the pressure in the chamber filter press is released through a relief valve and the filter press opens. The filter cakes fall, with the assistance of automatic shaking by means of a pneumatic cylinder, to the container arranged below the chamber filter press.

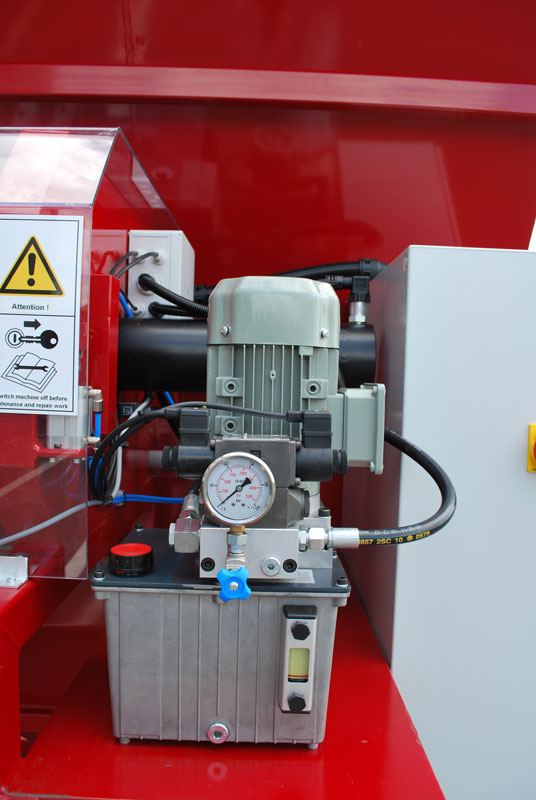

Technology

- Hydraulic opening and closing of the filter plates

- Positioning sensor for plate package

- Hydraulic system pressure make-up via pressure sensor of up to 250 bar

- Compressed air diaphragm pump for abrasive sludge for filling the filter plates

- Pressure relief of the filter press via 3-way valve

- Vibration bar with pneumatic cylinder

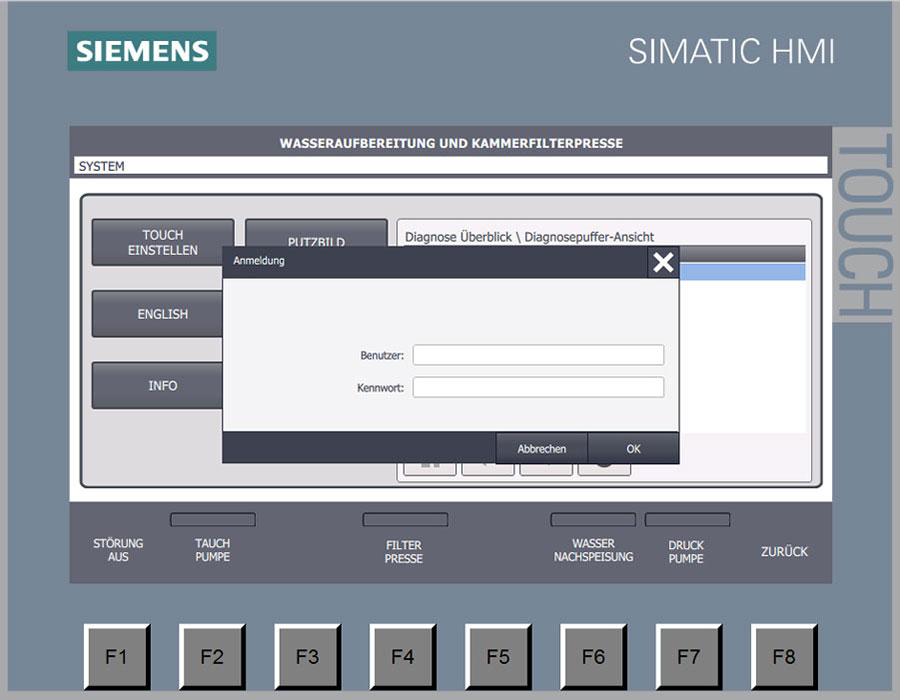

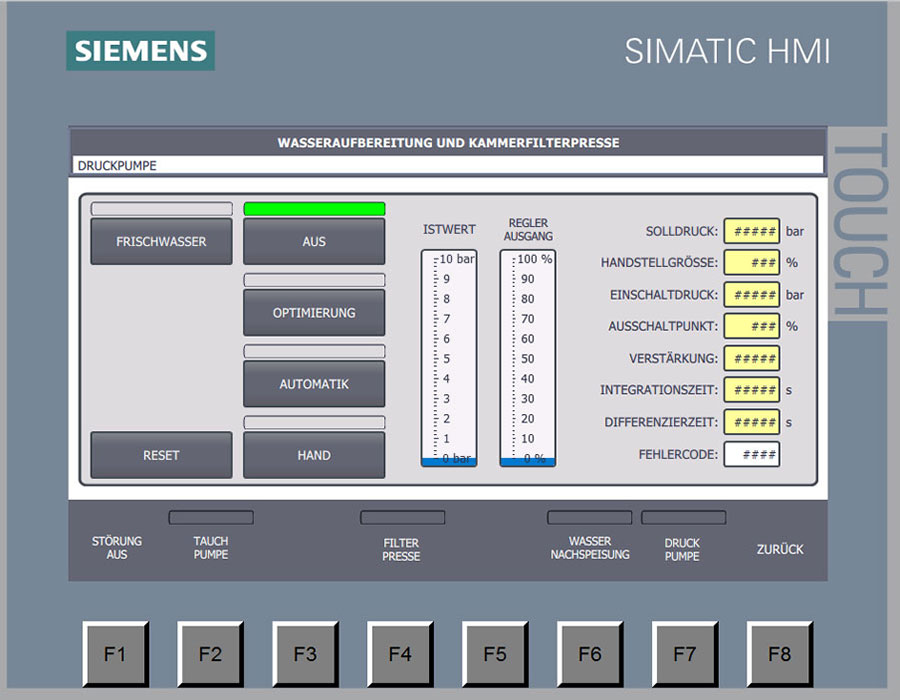

Control

The automatic control of ECS VMC plants takes place with a Siemens PLC. Operation and visualisation of the parameters take place via a touchscreen display. The plant can be adjusted perfectly to the requirements of your operation and water quality with the comprehensive parameter settings.

Operation of the VMP plant is possible in automatic mode and manually. In case of a fault, the control unit issues an error message in text format.

Our ECS VMP software is developed in-house. It is based on our knowledge of process water preparation and our practical experience gathered for over 20 years.

Technology:

- Siemens PLC

- 7” touchscreen display

- Automatic flow control of the overall process water cleaning

- Error text output in case of fault

Flow diagram

Gallery

Output and dimensions

| Type |

Output |

Dimensions (LxWxH) |

| VMP 30 |

15 m3/h |

2860 x 2120 x 2800 mm |

| VMP 40 |

20 m3/h |

3260 x 2120 x 2800 mm |

| VMP 50 |

25 m3/h |

3560 x 2120 x 2800 mm |

| VMP 60 |

30 m3/h |

3860 x 2120 x 2800 mm |

| Type |

Output |

Dimensions (LxWxH) |

| VMP 80 |

40 m3/h |

4560 x 2120 x 2800 mm |

| VMP 100 |

50 m3/h |

5360 x 2120 x 2800 mm |

| VMP 150 |

75 m3/h |

6960 x 2120 x 2800 mm |