Druckerhöhungsanlagen – EDR

EDR

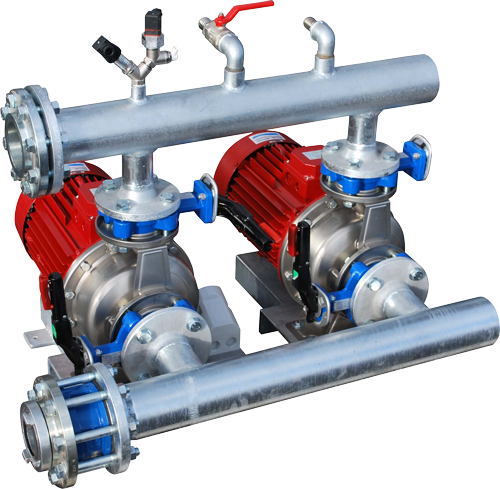

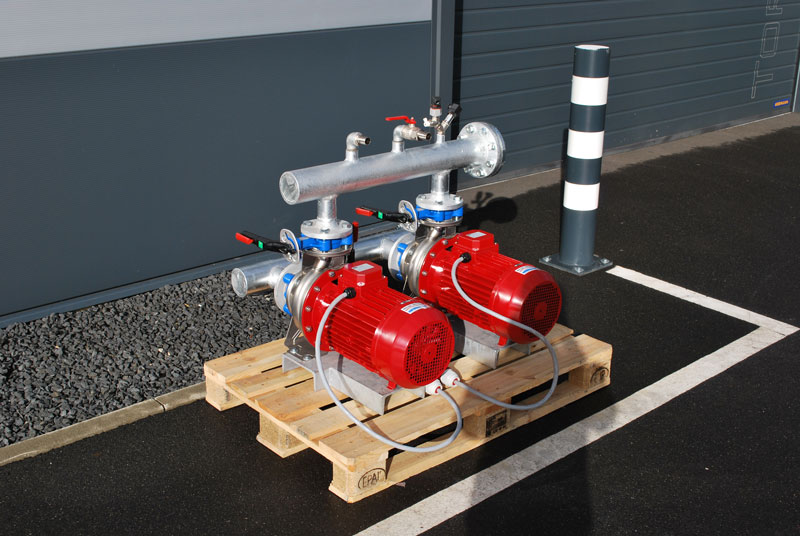

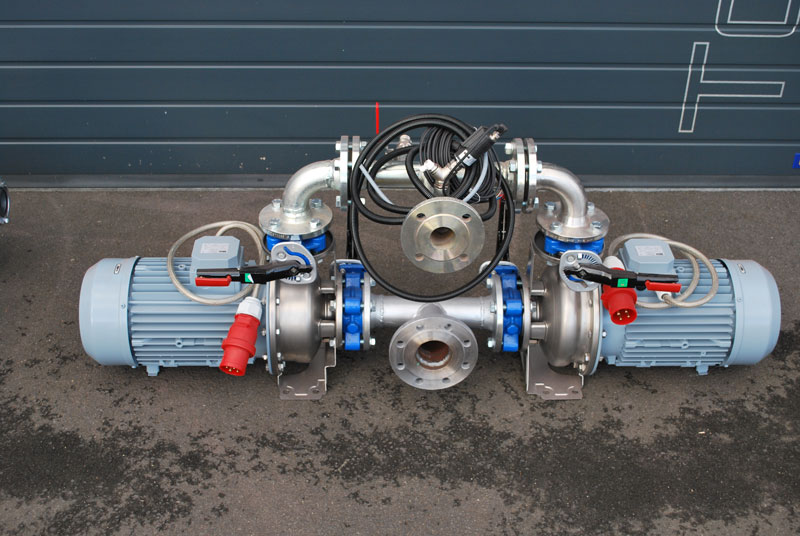

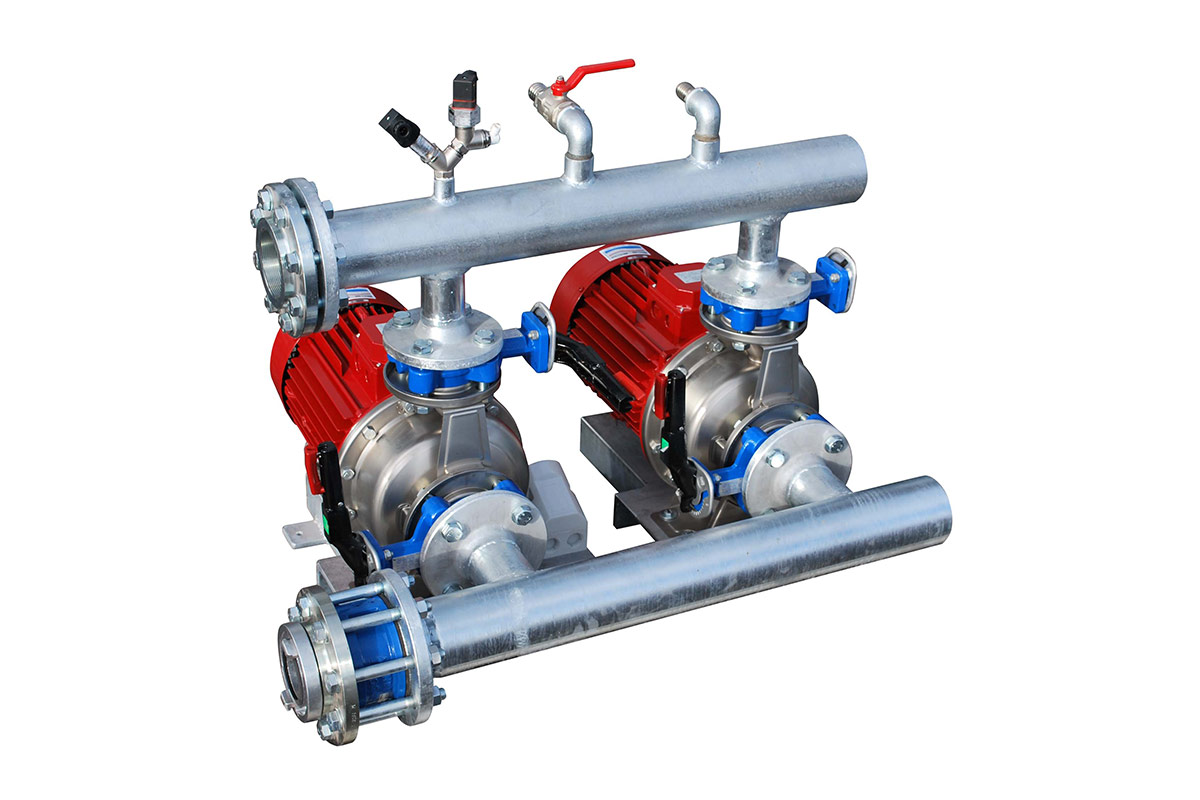

Customised pressure boosting stations with automatic pressure control, regulated operating pressure and temperature monitoring.

Pressure boosting station

Pressure boosting stations are used for fresh water supply of production machinery. The process water is brought to an operating pressure of approx. 4-6 bar by the pressure boosting station and supplied to the production machinery via pressurised water pipes.

EDR pressure boosting stations are equipped with a check valve, manometer, pressure switch, ventilation valve and compensation tank. In addition, the pressure boosting stations are monitored by a temperature sensor. In the process, it is assured that no damage occurs to the pressure boosting station in case of possible leakage in the pipeline system of the production machinery.

An optional frequency-controlled pressure boosting station is available. This offers the advantage of consistent water pressure with different fresh water intake volumes.

We would be happy to advise you in the tailored design of pressure boosting stations according to your individual requirements.

- Automatic pressure pump control with pressure sensor

- Regulated operating pressure

- Compensation tank to accommodate for pressure surges

- Check and ventilation valve

- Temperature monitoring with a sensor

- Regulated pressure control with a frequency converter for consistent pressure with variable intake volumes

- Redundantly installed backup pressure pump

- Regulated pressure control with a frequency converter for consistent pressure with variable intake volumes

- Redundantly installed backup pressure pump

Gallery

Output and dimensions

| Type | Motor output | Delivery rate at 4-6 bar |

|---|---|---|

| EDR 120 | 4,0 kW | 12 m3/h |

| EDR 210 | 5,2 kW | 21 m3/h |

| EDR 320 | 8,5 kW | 32 m3/h |

| EDR 450 | 11,0 kW | 45 m3/h |

| Type | Motor output | Delivery rate at 4-6 bar |

|---|---|---|

| EDR 650 | 15,0 kW | 65 m3/h |

| EDR 950 | 22,0 kW | 95 m3/h |

| EDR 1400 | 25,0 kW | 140 m3/h |

| EDR 2000 | 37,0 kW | 200 m3/h |